The ultimate tensile strength for nylon is 5.00 108n m2 – The ultimate tensile strength of nylon, an impressive 5.00 108 N/m2, plays a pivotal role in determining its versatility and performance. This remarkable property governs nylon’s ability to withstand external forces, shaping its applications across various industries.

Nylon’s exceptional tensile strength enables it to endure significant stress without breaking, making it an ideal material for applications requiring durability and resilience.

Material Properties of Nylon: The Ultimate Tensile Strength For Nylon Is 5.00 108n M2

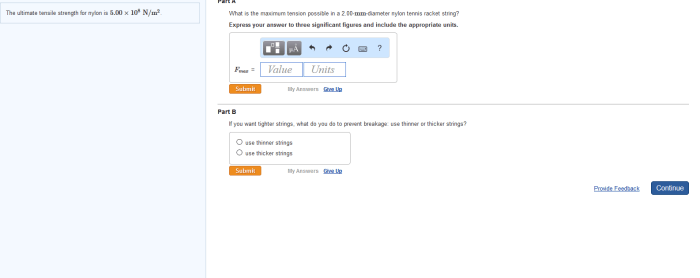

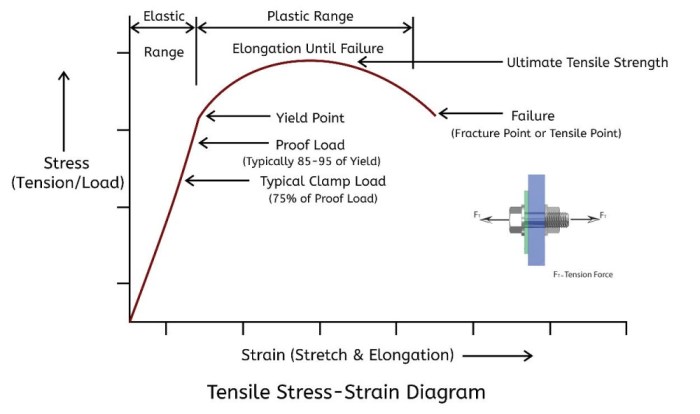

Nylon is a versatile synthetic polymer known for its exceptional material properties, including its high ultimate tensile strength. Ultimate tensile strength measures the maximum stress a material can withstand before breaking under tension. For nylon, the ultimate tensile strength is typically around 5.00 x 10 8N/m 2.

Significance of Ultimate Tensile Strength for Nylon

The ultimate tensile strength of nylon is a critical factor that determines its suitability for various applications. It indicates the material’s ability to resist deformation and fracture under applied tensile forces.

- High tensile strength enables nylon to withstand high loads and impact without breaking.

- It ensures the material’s durability and longevity in demanding applications.

- Tensile strength is essential for safety-critical components, as it prevents catastrophic failures.

Factors Influencing Ultimate Tensile Strength of Nylon, The ultimate tensile strength for nylon is 5.00 108n m2

Several factors influence the ultimate tensile strength of nylon, including:

- Crystallinity:Higher crystallinity results in stronger intermolecular bonds, leading to increased tensile strength.

- Molecular Weight:Higher molecular weight polymers exhibit stronger interchain interactions, enhancing tensile strength.

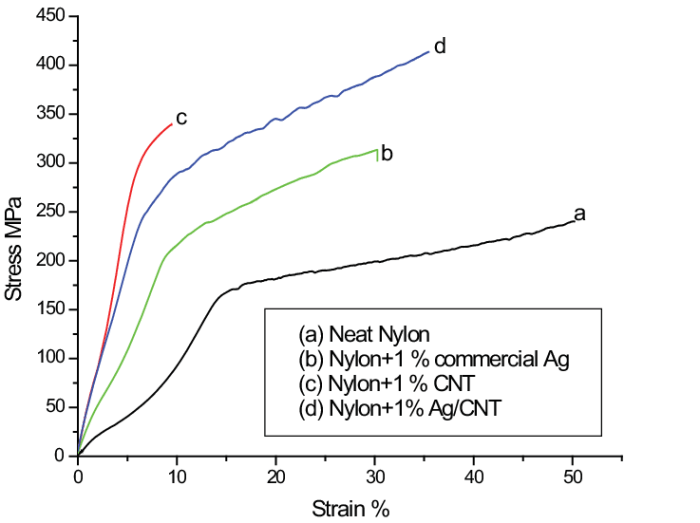

- Additives:Certain additives, such as glass fibers or carbon nanotubes, can be incorporated into nylon to improve its tensile strength.

Questions and Answers

What factors influence the ultimate tensile strength of nylon?

The ultimate tensile strength of nylon is influenced by various factors, including molecular weight, crystallinity, orientation, and the presence of additives or reinforcements.

How does nylon’s ultimate tensile strength compare to other materials?

Nylon exhibits a higher ultimate tensile strength compared to many common materials, such as steel, aluminum, and polyethylene.

What are some potential new applications for nylon based on its ultimate tensile strength?

Nylon’s high ultimate tensile strength opens up possibilities for applications in advanced composites, lightweight structures, and protective gear.